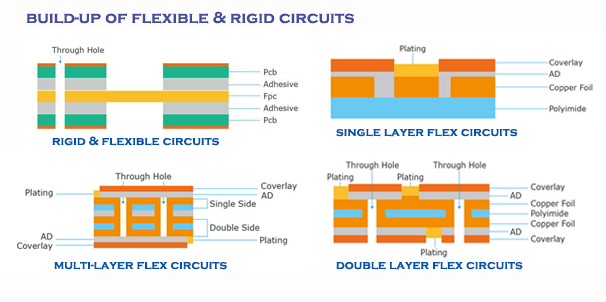

Single-sided flexible circuits have a single conductor layer made of either a metal or conductive (metal filled) polymer on a flexible dielectric film. Component termination features are accessible only from one side. Holes may be formed in the base film to allow component leads to pass through for interconnection, normally by soldering. Single sided flex circuits can be fabricated with or without such protective coatings as cover layers or cover coats, however the use of a protective coating over circuits is the most common practice.

Double-sided flex circuits are flex circuits having two conductor layers. Theses flex circuits can be fabricated with or without plated through holes. Depending on design requirements, double-sided flex circuits can be fabricated with protective coverlayers on one, both or neither side of the completed circuit but are most commonly produced with the protective layer on both sides.

Multilayer flex has three or more layers of conductors are known as multilayer flex circuits. Commonly the layers are interconnected by means of plated through holes, though this is not a requirement of the definition for it is possible to provide openings to access lower circuit level features. The layers of the multi-layer flex circuit may or may not be continuously laminated together throughout the construction with the obvious exception of the areas occupied by plated through-holes.

Rigid-flex circuits are a hybrid construction flex circuit consisting of rigid and flexible substrates which are laminated together into a single structure.The layers of a rigid flex are also normally electrically interconnected by means of plated through holes.Rigid-flex boards are normally multilayer structures.

Contact: Mr. Michael Zou

Phone: +8615989475697

Tel: +86-755-27678837

Email: mc@pcgl-electronics.com

Add: 206, Huichuang2018 Creative Industrial Park, Gushu1st Road, Bao’ an District, Shenzhen City, China.