1. Raw Material Quality Control

• Supplier Selection: Work with reliable suppliers to ensure quality of materials like laminate, soldermask, prepreg etc.

• Incoming Inspection: Check each batch of materials for key specifications and quality compliance.

2. Production Quality Monitoring

• Process Control: Set up QC checkpoints at critical stages (e.g., lamination, drilling) to maintain consistency.

• Parameter Monitoring: Track key parameters like temperature and humidity to ensure stable processes.

3. Inspection and Testing

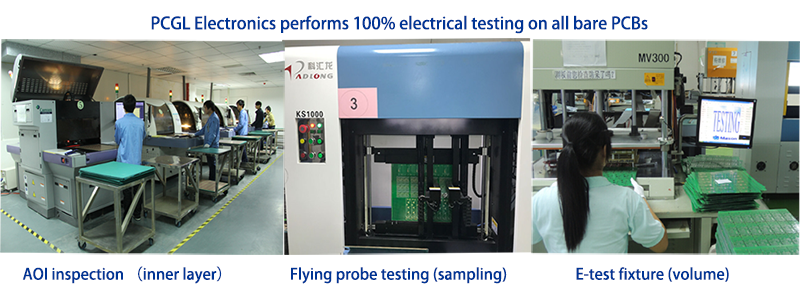

• AOI (Automated Optical Inspection): Check circuit patterns for issues such as shorts or opens.

• Electrical Testing: Use flying probe or E-testing to verify electrical connectivity.

• Final Inspection: Confirm compliance through checks on appearance, dimensions, and electrical performance like copper thickness, impedance control.

4. Reliability Testing

• Environmental Testing: Simulate temperature and humidity changes to test reliability.

• Lifespan Testing: Assess durability under simulated real-use conditions.

5. Quality Certifications

Our factory holds the following certifications to support rigorous quality standards:

• ISO 9001: For general quality management.

• ISO 14001: For environmental management.

• UL and RoHS: Safety and environmental compliance.

• IATF 16949: Automotive industry certification focused on defect prevention and risk management.

APQP: Manages quality from design to production.

PPAP: Ensures product and process consistency.

FMEA: Identifies and addresses potential risks.

6. QC Team and Training

• Experienced QC Team: Skilled in detecting and resolving quality issues.

• Ongoing Training: Regular updates on quality techniques and standards.

7. Data-Driven Traceability

• Production Data: Detailed records enable fast tracing of any quality issues.

• Continuous Improvement: Customer feedback is used to enhance processes.

8. Customer Commitment

• Quality Assurance: Strict inspection before shipping to ensure all products meet quality standards.

• After-Sales Support: Provides responsive service and support to ensure customer satisfaction.

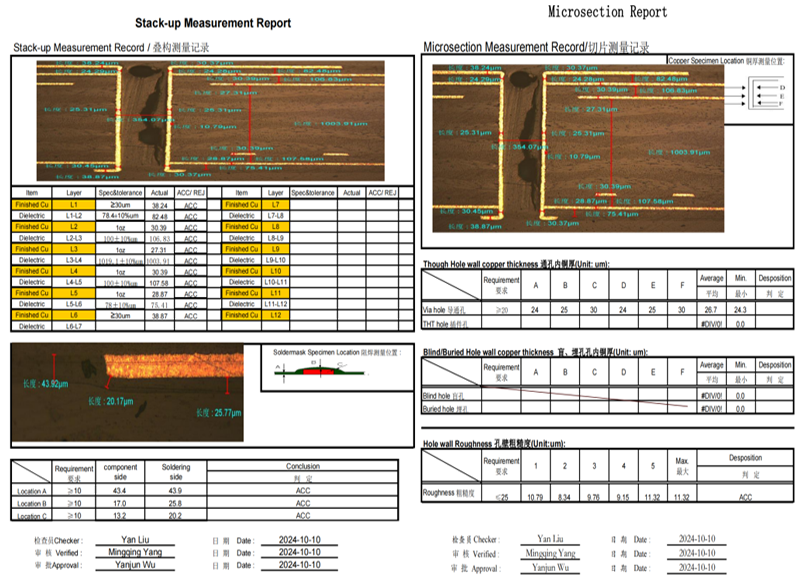

The following TESTING REPORTS will be dispatched with our PCBs in the carton on every batches

1. RoHS Compliance Report (COC)

2. Outgoing Inspection Report

3. Electrical Test Report

4. Micro Sections

5. Micro Sections Report

6. Solderability Sampling Boards

7. Test Coupon (For Impedance Controlled PCBs)

8. TDR Test Report (For Impedance Controlled PCBs)

Contact: Mr. Michael Zou

Phone: +8615989475697

Tel: +86-755-27678837

Email: mc@pcgl-electronics.com

Add: 206, Huichuang2018 Creative Industrial Park, Gushu1st Road, Bao’ an District, Shenzhen City, China.