Plastic injection molding is the preferred manufacturing process for producing large quantities of low-cost plastic components. It features high precision, excellent repeatability, and minimal post-processing requirements. Our company has in-house mold design and manufacturing capabilities and offers comprehensive supply chain solutions. We provide a wide range of thermoplastic and thermosetting plastics to meet various strength and functional requirements. With 57 injection molding machines, including multi-color models, and a maximum clamping force of 650T, we serve industries such as automotive, consumer electronics, security, and medical sectors.

Design for Manufacturability (DFM) Report

The DFM report is a detailed technical document created in the early stages of product development and mold manufacturing. It analyzes and optimizes product designs to ensure they are practical, efficient, and cost-effective for production. Serving as a crucial bridge between mold manufacturers and product developers, the report identifies and resolves potential issues, minimizing manufacturing risks while improving efficiency and product quality.

Key Aspects of the DFM Report:

Resin Selection (Material Choice):

Analyzing resin characteristics, including thermoplastics or thermosetting plastics, heat resistance, chemical resistance, flowability, and shrinkage. This ensures the chosen material meets functional requirements while being compatible with the molding process.

Draft Angle:

Evaluating the draft angles on all surfaces to ensure smooth ejection of parts from the mold, preventing issues like difficult demolding, surface scratches, or molding defects. The angles are optimized to maintain functionality.

Wall Thickness Design:

Analyzing the uniformity of wall thickness and the rib-to-wall ratio to avoid thin or uneven sections in the design. This reduces stress concentration and warping, improving the strength and stability of the final product.

Gate Design:

Determining gate types and positions, such as pinpoint gates, edge gates, or submarine gates, and analyzing their impact on product appearance, strength, and production efficiency. Ensures uniform filling, minimizes weld lines, voids, and shrinkage, and meets surface finish requirements.

Mechanical Structure and Parting Line:

Describing the mold’s mechanical structure (e.g., sliders, lifters, inserts) and ensuring the parting line placement does not compromise the part’s appearance or function. Ensures smooth mold operation and avoids production difficulties or mold damage due to poor design.

Surface Finish and Markings:

Defining surface finish requirements (e.g., polishing, texturing, sandblasting) and specifying the position of engravings or markings. Ensures the product meets aesthetic and functional standards, with precise process specifications to avoid errors.

Our DFM reports are not only the foundation for mold manufacturing but also a cornerstone of successful product realization. For industries such as automotive, medical, and consumer electronics, where quality and aesthetics are critical, DFM analysis is indispensable.

Material:

We extensively utilize a variety of resin materials, categorized as follows:

Engineering Plastics:

Acetal (POM), Acrylic (PMMA), ABS, Nylon (PA) and Glass-Filled Nylon, Noryl (PPO and PS), PC, PET, PBT, PEI, Peek, PPS.

General Plastics:

PP, PS, PU, rigid and soft PVC.

High-Performance Plastics:

PES, Cellulose Acetate (CA).

Elastomers:

Thermoplastic Elastomers (TPE), Thermoplastic Rubber (TPR).

These materials feature excellent properties such as strength, heat resistance, chemical resistance, and processability, meeting the diverse needs of various industries while delivering reliable and efficient solutions.

Surface Treatments:

Through plastic molding, we can achieve various surface finishes, including sandblasting, texturing, standard polishing, mirror polishing, laser engraving, printing, electroplating, brushing, and marble patterns.

Order Process:

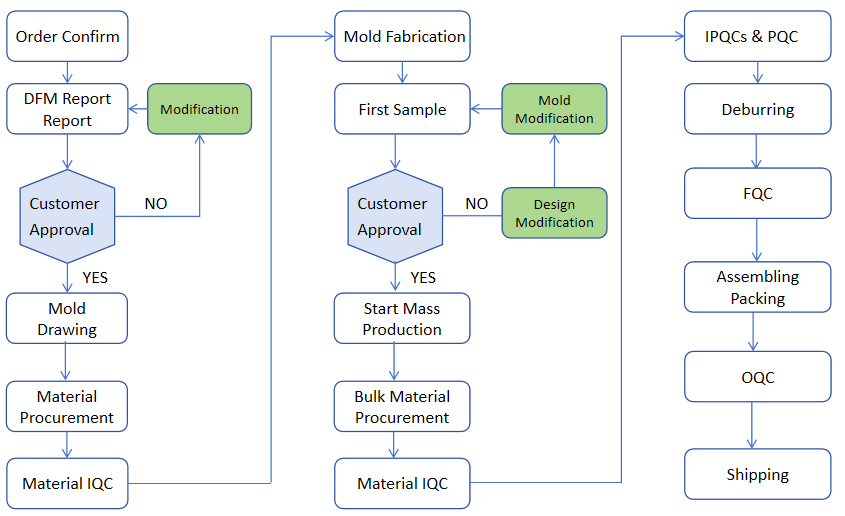

After order confirmation, our engineers will provide the customer with a DFM (Design for Manufacturability) report for approval. Upon customer approval of the DFM report, we will begin designing mold drawings and proceed with mold manufacturing. Once the mold is completed, we will produce a few pre-production samples for testing. If the dimensions are correct, the samples will be sent to the customer for final confirmation. Should testing fail, we will modify the mold or adjust molding parameters to create new samples for re-testing. After the sample is approved by the customer, we will procure raw materials and conduct quality inspections. Subsequently, materials will be blended, molded, and trimmed, with multiple inspections carried out during production. Finally, we will arrange for assembly and packaging. Once the entire order is ready, a packing list will be sent to the customer to arrange shipment.

Our company adheres to a rigorous quality control process, implementing 100% inspection for every order to ensure high standards across all stages, from IQC (Incoming Quality Control) to OQC (Outgoing Quality Control). Below are our quality control measures:

Raw Material Inspection (IQC):

Pre-Production Samples:

Production Process:

Post-Packaging and Assembly Inspection (OQC):

Contact: Mr. Michael Zou

Phone: 15989475697

Tel: 0551-64211661; 0755-27678837

Email: mc@pcgl-electronics.com

Add: 206, Huichuang2018 Creative Industrial Park, Gushu1st Road, Bao’ an District, Shenzhen City, China.